Main function of the task is to assist the general public master some fascinating and significant details about engineering and thermal engineering.

Thorough performance: Combination air valves are made to supply a comprehensive Resolution, such as air release, vacuum relief, and surge defense, producing them appropriate for many pipeline devices.

Understanding the functionalities and appropriate applications of these many types of valves might help in earning educated conclusions for equally industrial purposes and every day utilities.

The anti-slam unit is beneficial at highpoints exactly where column separation or rapid changes in velocity occur. Column separation might be predicted by computer transient Assessment, but the next common suggestions can be utilized to assist Find anti-slam devices:

These are uncomplicated, cheap, and have no transferring sections, but are fewer adaptable to variations in functioning conditions as compared to other types of expansion equipment.

Second, a nicely support air valve is surely an air/vacuum valve Outfitted using a throttling unit or an anti-slam unit (4-in and larger valves) for use with vertical turbine pumps.

Coaxial valves are a very good substitute for ball valves in lots of on/off applications. Actually, They can be a more economical, smaller sized, lighter, safer and faster substitute. Drawbacks of coaxial valves include decrease circulation capability and minimal fluid compatibility.

Valves help keep and regulate system problems like temperature and pressure within just wanted limits. That is vital for processes in which certain situations are necessary for optimum efficiency and solution top quality.

The air/vacuum and air Launch valves are put together in The mix air valve, making it an awesome choice for substantial spots. In one assembly, a combination valve has a little air launch orifice as well as a significant air/vacuum port.

World valves are employed to manage flow inside of a pipeline. They've a spherical human body along with a movable disk-form element that presses from a stationary ring seat, usually in a right angle to your pipe.

Due to this fact, these valves tend to be used in extreme company scenarios — Imagine corrosive environments like oil refineries and chemical crops.

Together with the lack of performance and rise in Vitality prices, pumps have to work tougher to realize the required flow fee.

When picking air valves, size performs an important function in pinpointing the air move capability on the program. The size from the valve instantly impacts the amount air This Site can go through it at a specified time. It is crucial to settle on a sizing that matches the particular specifications from the procedure to be sure best air circulation without triggering any constraints or bottlenecks.

Closing out the list of different types of valves as well as their uses could be the angle navigate to this website seat valve, A different style of valve that will serve as an alternative to get a ball valve in on/off applications. Seat angle valves utilize a designed-in pneumatic actuator that may be double acting or spring return.

Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Joseph Mazzello Then & Now!

Joseph Mazzello Then & Now! Charlie Korsmo Then & Now!

Charlie Korsmo Then & Now! Keshia Knight Pulliam Then & Now!

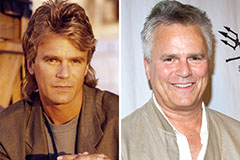

Keshia Knight Pulliam Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!